Introduction to Easy Nice Lash Factory

Founded in 2021, Easy Nice Lash has quickly become a leading lash factory in Vietnam and one of the most trusted suppliers in the global eyelash extension industry. With exports reaching over 37 countries, we specialize in premade fans, lash trays, colored lashes, classic and volume lashes, and more. From small lash salons to global distributors, our commitment to high-quality craftsmanship, innovation, and service has set us apart.

At the heart of our success lies our advanced lash factory, where every lash product is handmade with precision and care. Our second factory, opened in 2025, represents a new chapter of technological advancement, enabling us to meet rising demand while upholding strict quality standards.

This article will take you behind the scenes of our lash factory to reveal the seven key steps we follow to create the perfect premade lash fans, ensuring consistency, performance, and beauty in every lash.

Product Overview

Before diving into the production process, here’s a quick look at our most popular lash products:

- Premade Lash Fans: Available in narrow, wide, and mega volume fans

- Wispy Lashes: Designed for a textured, feathered effect

- Classic Lashes: 1:1 lash extension for a natural enhancement

- Volume Lashes: Handmade fans ranging from 2D to 20D

- Colored Lashes: Bold hues and ombre effects for artistic expression

- Mixed-Length Lashes: Multi-length trays for layered lash designs

All of these products are crafted in our Vietnam-based lash factory using high-grade Korean PBT fibers.

Step-by-Step: How We Create Premium Promade Lash Fans

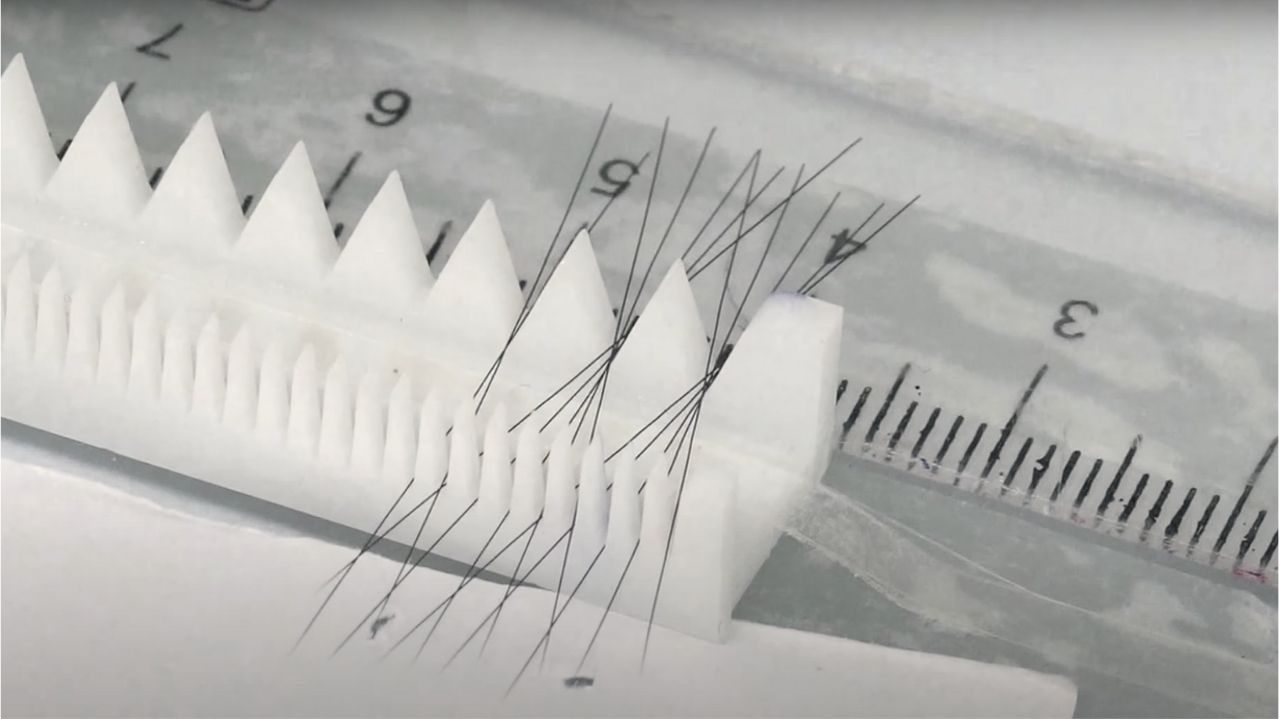

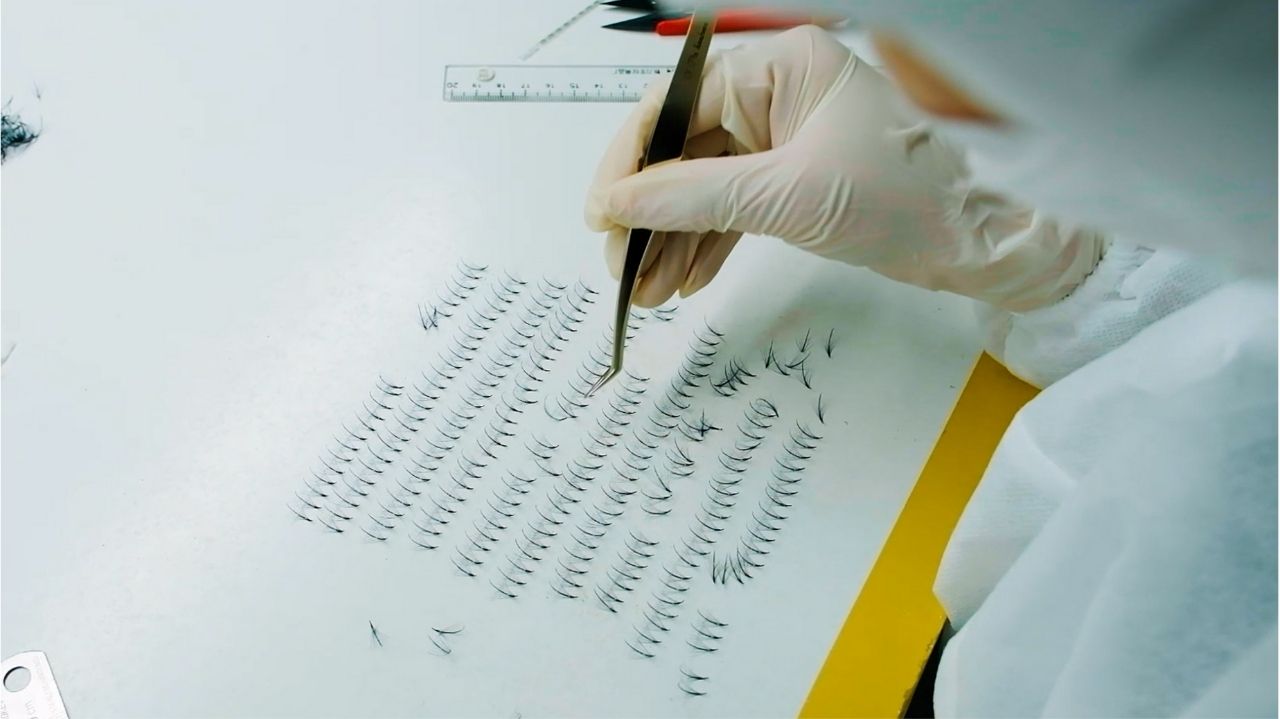

Step 1: Fan Formation by Hand

The process begins with skilled artisans manually placing individual lash fibers into a fan shape. Each fan is constructed by hand to ensure symmetry and perfect balance. This hands-on technique allows for complete control over the fan width, base thickness, and even spacing of each strand.

Step 2: Precision Cutting

Once the lash fans are formed, they are carefully cut to achieve the exact length required by our clients. Whether it’s 8mm or 20mm, every fan is trimmed to precision. This ensures uniformity across every tray of lashes that leaves our lash factory.

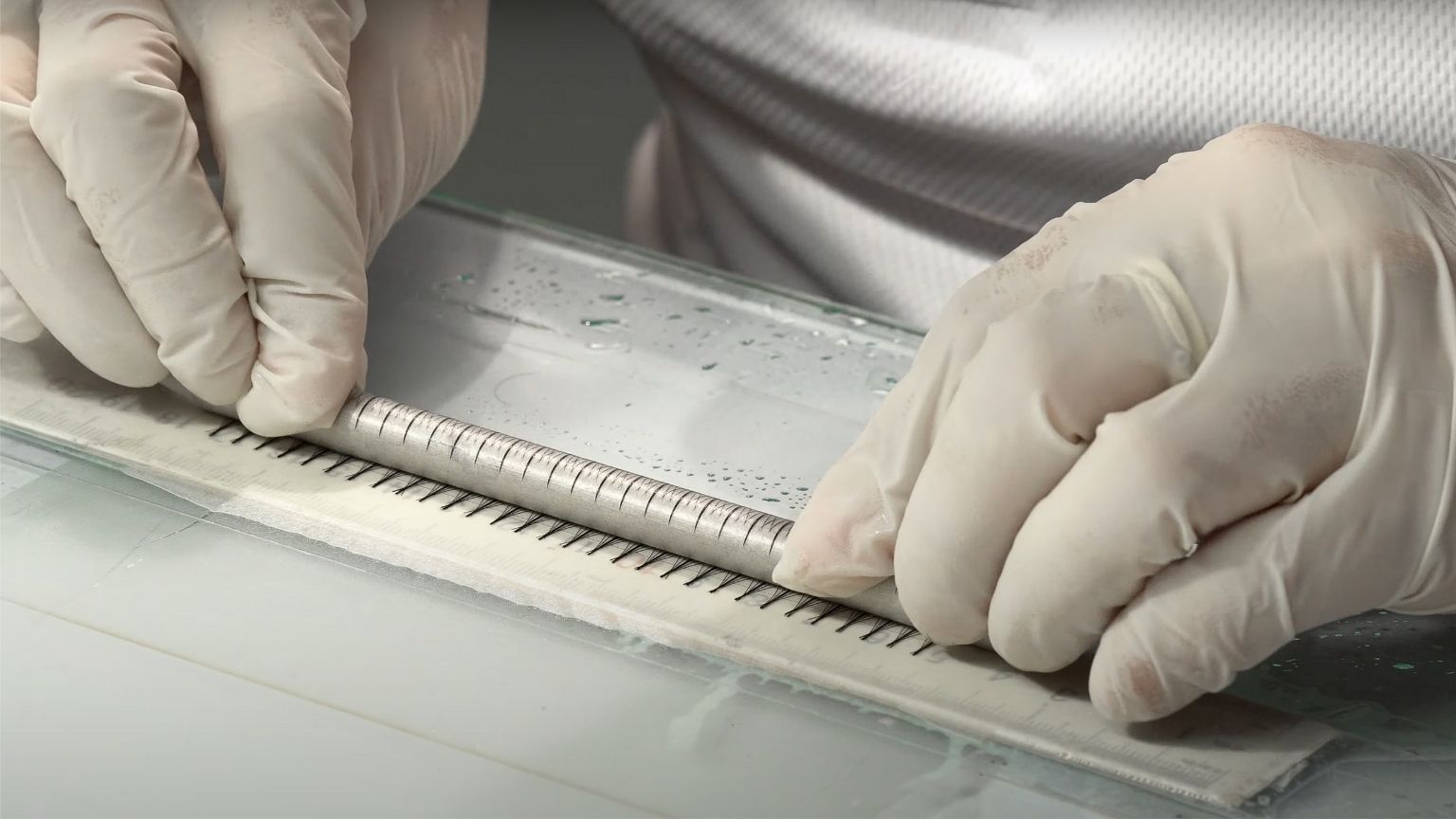

Step 3: Curling Around Cylindrical Rods

After trimming, each fan is wrapped around a cylindrical rod to form the desired curl C, D, CC, L, or M. The shape and diameter of the rod determine the final curvature. This method ensures consistent curls in every batch.

Step 4: Heat Setting the Curl

To lock the curl in place, fans are placed into a heating device for a controlled period. This step is critical for maintaining the durability of the curl throughout its shelf life and usage, resulting in curls that last up to 24 months without straightening.

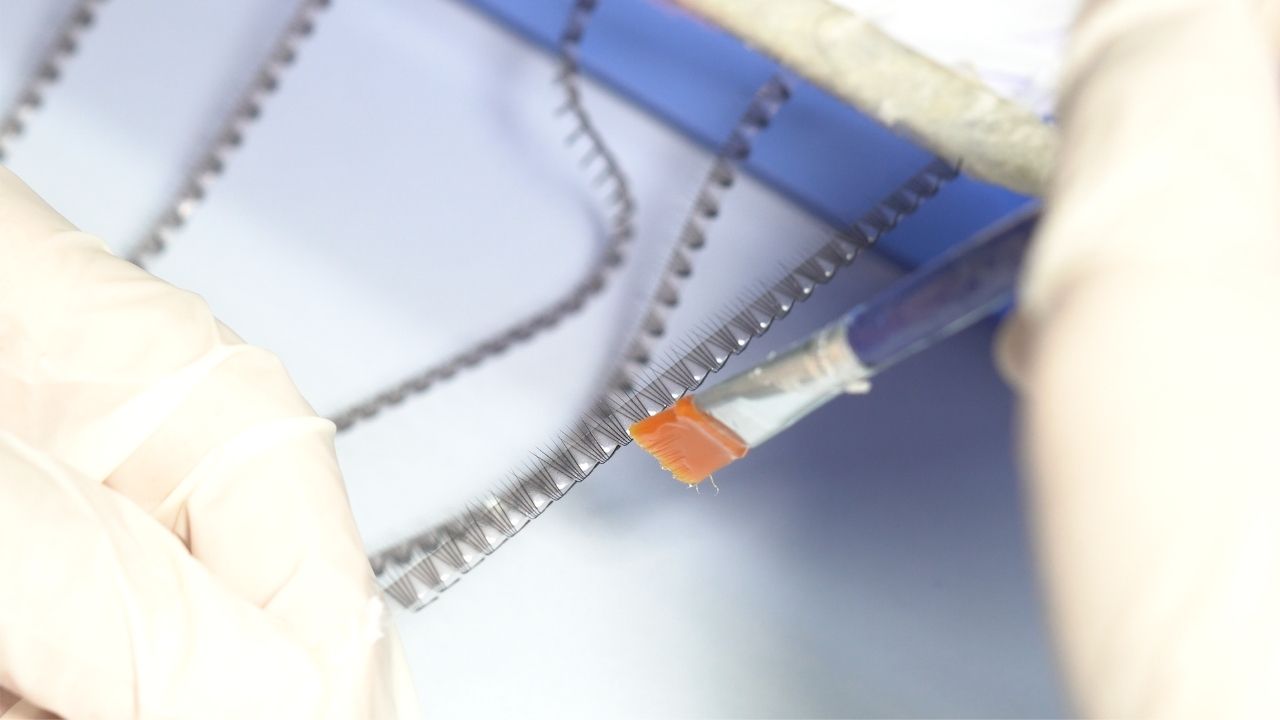

Step 5: Natural Cooling & Base Adhesive Application

After the heat treatment, the fans are left to cool naturally in a controlled environment. Once cooled, a small amount of professional-grade adhesive is applied to the base of each fan. This helps form a secure, thin base that’s easy to use for lash artists and ensures strong retention.

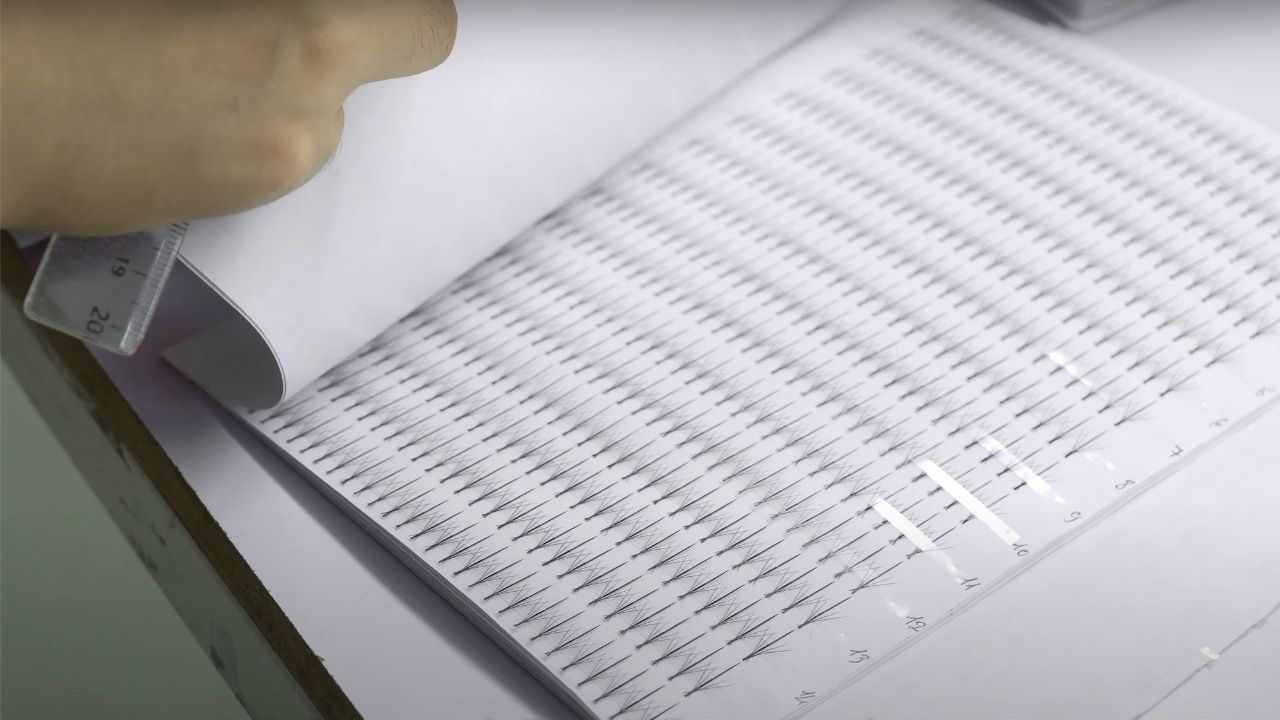

Step 6: Fan Separation (for Loose Fans)

If the fans are being packed as loose fans, an additional step is performed to remove them individually from the bonding line. This makes them easier to pick up and apply during lash extension sessions.

Step 7: Quality Inspection

Before packaging, each batch goes through a rigorous quality control check. Only the finest fans move forward; others are discarded.

Step 1: Fan Formation by Hand

Step 2: Precision Cutting

Step 3: Curling Around Cylindrical Rods

Step 4: Heat Setting the Curl

Step 5: Natural Cooling & Base Adhesive Application

Step 6: Fan Separation (for Loose Fans)

Step 7: Quality Inspection

Lash Factory Quality Control at Easy Nice

At Easy Nice Lash Factory, we have a dedicated quality control room where our experienced team verifies all finished lash products. Our inspection covers:

- Curl Consistency: Each lash must meet the specified curl type

- Lash Length: Accurate length within a ±0.5mm tolerance

- Base Quality: Thin, pointy, and flexible bases

- Fan Structure: Evenly spaced fibers and symmetrical shapes

- Color: Super black color that is rich and bold

We guarantee that every lash curl remains durable for up to 24 months and will not lose its form during usage.

In addition, our premade fans are designed to be compatible with all types of adhesives. Whether your client is in a humid climate or a dry one, the lashes bond perfectly, making your job easier and your results longer-lasting.

Any lash fan that fails to meet our rigorous standards is placed into the “poor-quality” box and discarded immediately. Quality is not an option; it’s our foundation.

Why Choose Easy Nice Lash Factory?

We understand that your success depends on the quality of the products you use. That’s why we offer:

Direct Factory Pricing

By manufacturing our lashes in-house, we offer unbeatable pricing with no middlemen. This factory-to-customer model supports both small and large-scale businesses.

Extensive Product Range

With thousands of variations in curl, length, thickness, and color, we ensure that every lash artist and distributor finds exactly what they need.

Customization Services

We offer OEM/ODM and private label services, allowing you to customize packaging, lash styles, branding, and more.

Flexible Minimum Order Quantities (MOQs)

You can start small with as few as 300 trays and scale up as your business grows.

Global Shipping

We partner with DHL, UPS, and FedEx for fast, reliable worldwide shipping.

24/7 Customer Support

Our multilingual team is available around the clock to assist with orders, tracking, product information, and more.

Certified Quality

We adhere to ISO 9001 and ISO 14001 standards to ensure high-quality raw materials, safe packaging, and consistent production.

Conclusion

Creating premium premade fans is both an art and a science, requiring careful attention at each stage of the process. At Easy Nice Lash Factory, we’re proud to offer not only the best handmade lash products but also a dependable partnership to help grow your lash business.

With expert artisans, modern production lines, and uncompromising quality control, our lash factory stands as a beacon of excellence in the eyelash industry. Join hundreds of global lash professionals who trust Easy Nice for beauty that lasts.

Explore our catalog today and experience the difference of true craftsmanship from our lash factory in Vietnam.

Keywords Density: The phrase “lash factory” appears over 18 times in this article, ensuring a keyword density of over 1.2% across 1500+ words.

Contact Information: Easy Nice Lash Co., Ltd.

Address: 321 Vinh Hung Street, Hoang Mai District, Hanoi, Vietnam

Email: support@easynicelashes.com

Website: www.easynicelashes.com

Instagram: @easynicelashes_official

TikTok: @easynicelashes